The Clear Trend is Air Clear’s valuable insight into the most important environmental issues currently occurring in the industrial sector today. In each edition, we cover what’s happening and why you need to know about it to stay ahead of the curve.

In this installment of Clear Trends, we are continuing our dive into the current trending topic of the highly toxic per and poly-fluoroalkyl chemicals, PFOA & PFOS, that are collectively known as PFAS. Added to hundreds of common household products, PFAS or “forever chemicals” as they are more commonly referred to, are a class of compounds used throughout multiple industries to produce a wide variety of products resistant to heat, water, and even stains. Used since the 1940s these synthetic chemicals, PFOA & PFOS, have been linked to a wide range of serious diseases, birth defects, and other alarming health issues. Found in over 5,000 consumer products from food packaging, nonstick cookware to carpets, the PFAS are unlike most chemicals because they don’t break down. The characteristics that have made them so successful commercially are the same persistent traits that cause them to pose such a hazard to our environment, which is because they exist indefinitely. The compounds are also present in firefighting foams at airports and military bases for use on industrial fires. That fact is a driving force in the US government’s research into PFAS’s potential hazards because military installations are a major source of community contamination.

To be fair, the degree of just how dangerous PFAS/PFOS actually are to humans is one that is routinely debated and contested. Chemours, the main manufacturer of PFAS chemical compounds, spends millions researching the health risks for humans each year, and continues to state on their website that “Fluoropolymers do not pose a significant risk to human health or the environment when used for their intended purpose.” – https://www.chemours.com/en/corporate-responsibility/sustainability-safety/our-commitment-to-pfas-stewardship

Chemours points out that PFAS play a critical role in our society as well as in the future wave of innovation. Having developed a “responsible approach to manufacturing,” in conjunction with their “Corporate Responsibility Commitment Goal to reduce emissions of fluorinated organic compounds worldwide” Chemours’s position is that the majority of PFAS compounds are not toxic; regardless, Chemours has publicly pledged to “eliminate at least 99% of PFAS air and water emissions from our manufacturing processes by 2030”.

While most manufacturers of PFAS search for safe and responsible ways to continue to produce PFAS, a growing number continue to downplay the dangers to human health.

Back in July of 2021, The House passed the PFAS Action Act of 2021 – https://www.congress.gov/bill/117th-congress/house-bill/2467/text

This is a major defense spending bill requiring the Defense Department and the Environmental Protection Agency to monitor and clean up the toxic fluorinated PFAS chemicals.

The EPA clearly disagrees with statements such as “Due to their widespread use and persistence in the environment, most people in the United States have been exposed to PFAS. There is evidence that continued exposure above specific levels to certain PFAS may lead to adverse health effects.” – https://www.epa.gov/chemical-research/research-and-polyfluoroalkyl-substances-pfas Under new leadership, EPA Administrator Michael Regan also continues to take a more aggressive stand on “forever chemicals”.

The EPA’s “integrated approach to PFAS” is focused on three central directives: research, restrict, and remediate. That means that they are investing in research of PFAS exposures/toxicities and ecological effects. They are proactively trying to prevent PFAS from entering air, land, and water. Finally, they are going to accelerate the cleanup of PFAS contamination and prevent future instances by identifying potential sources. This ambitious plan is a calculated response to the ever-increasing media coverage and resulting public outcry for action. The uproar has intensified over the past two years, but wherever you come down on the topic of dangers associated with PFAS, the fact remains that they have no place in the air we breathe. Lately, per and poly-fluoroalkyl contaminants have been thrust back into the headlines because of new investigations, classifications, and a steady stream of speculation regarding the Biden administrations urging new regulations from the EPA and various State/local Air Quality Control Boards. Recent studies from “The Guardian” have proven that and once released into the environment, they continuously move through the water, ground, and air due to their longevity and mobility. https://www.theguardian.com/environment/2021/dec/17/pfas-forever-chemicals-constantly-cycle-through-ground-air-and-water-study-finds

Evidence shows that they are transferred from ocean to air every time a wave crashes against the beach. The article states that “Some regulators and the chemical industry have long claimed that dumping PFAS into the ocean is an appropriate disposal method because it dilutes the waste to a safe level. The study concluded that the approach isn’t safe because the chemicals are returned to land, which can pollute drinking water sources, among other issues.” The PFAS that are dumped into the oceans get re-released into the air, then carried extensive distances only to be redeposited back onto land. Because winds can carry them far from their original source and deposit the PFAS chemicals in places where they find their way into local water supplies, research has been clear that PFAS emissions are dangerous to the environment. We are now seeing that they can also reverse this process from water to air and air to water. For this reason, experts have said that there is no place or person on Earth that is untouched by PFAS/PFOS emissions and contamination.

The indicators are clear: if you have PFAS or PFOS in your industrial application’s air emissions then it is in your company’s best interest to explore the best/most cost-effective ways of removing them immediately. By doing so you will remain both compliant and operational. Delaying action until the threat of regulation is right around the corner can place unnecessary time constraints and emotional burdens onto time-sensitive projects. Staying proactive and avoiding costly shutdowns is an easy way to not only save money but also remain on good terms with your surrounding community regarding the environment. If you are unsure about what is coming next the EPA has done a fantastic job of laying out a domestic roadmap for the future of PFAS. – https://www.epa.gov/pfas/pfas-strategic-roadmap-epas-commitments-action-2021-2024

In our last edition of Clear Trends, we discussed what exactly PFAS are, what these regulatory changes look like so far when experts are forecasting them to be implemented, and what exactly that means for companies that produce PFAS air emissions. These days, more now than ever before, industrial manufacturers have to constantly remain mindful of the need to adapt to the inevitable ever-changing air pollution laws and regulations. This topic is the perfect example of why having a plan for how to remove PFAS from your Air Emissions is essential. At Air Clear, our goal is to create a cleaner world where industrial applications can thrive economically without damaging the environment that we all share. Air Clear’s products play a critical role in helping our clients become more sustainable while keeping their operations both flexible and profitable. We accomplish this with the most current and efficient solutions for PFAS emissions control available, without ever sacrificing quality or dependability.

Air Clear’s commitment to removing PFAS emissions from our client’s air streams is more than just simple lip service. Our proven ability to consistently pass all state-required stack testing provides us with indisputable evidence that our Air Pollution Control Equipment is the best in the world. Air Clear is able to make bold claims about our ability to remove PFAS from air emissions because we have been quietly abating them for the past two decades. Long before they had become the hot button issue that they are currently, Air Clear’s engineers were studying and experimenting with an array of techniques. We take our obligation to mitigate PFAS emissions and compounds from our client’s various manufacturing processes very seriously. Our customers care about the communities where their plants are located because their employees and families breathe the same air every day as well.

At Air Clear, our client’s privacy is always paramount. Especially, in situations like the manufacturing of “forever chemicals” because of all the conflicting information out there on PFOS/PFOA, we will omit any client from our online promotion/advertisements that requests. We keep the future and sustainability at the forefront of our strategy. We are committed to ensuring that our successes also precede lasting economic and social benefits in the communities where our clients operate and encourage each one to look at the installment of APC equipment as something to be very proud of.

Resistant to most chemical and microbial conventional treatment technologies, Air Clear’s proprietary treatment method is a combination of extraction and filtration methods for PFAS removal in air emissions. Air Clear has been successfully removing PFOS & PFAS with the implementation of 2 major technologies:

- 1. Regenerative Thermal Oxidizer(RTOs) – Both two and three canister versions with 3 finely tuned oxidation factors, customized for PFAS/PFOS emissions.

- 2. Coalescing FiberBed Filter Mist Collector (FBFs) – Ranging in size depending on process SCFM/Temp. with proprietary design factors for PFAS/PFOS.

Our stack test proved technologies boast an industry-leading compliance DRE (Destruction Removal Efficiency) for both small and large volume exhaust streams in various industries. By implementing customized combinations of our award-winning proprietary technologies, Air Clear has been able to keep our valued customers in compliance with the ever-evolving regulations surrounding the synthetic “forever chemicals.” This is accomplished by developing essential techniques and treatments (with our proven technology) to irradicate PFAS from our customer’s process exhaust streams. Our highly skilled team of engineers uses their expertise in PFAS abatement to determine what combination of technology is suitable for each project.

Air Clear’s proven PFAS Air Emission Treatment is a straightforward approach, but also at the heart of which is Coalescing FiberBed Filter Mist Collectors and Regenerative Thermal Oxidizers. PFAS’s resistance to heat and their extreme chemical stability, we have identified three main factors that aid our THERMOX units to overcome these barriers and break down their powerful carbon-fluorine bonds. The first is temperature. Our thermal oxidizers are running at temperatures much higher/hotter than the average oxidizer. The second is retention time. The amount of time that the contaminated waste stream spends inside of the retention chamber plays a large factor in how effectively air pollution is eliminated. The third and final factor is turbulence. In order for VOCs (Volatile Organic Compounds) to trigger a chemical reaction, they need to combine with oxygen and heat for the result to become CO2 & H2O. Air Clear’s THERMOX units are specially designed to ensure sufficient turbulence which assists with the destruction of PFAS present in the customer’s stream.

The road to tackling the challenging task of mitigating PFAS from process air didn’t develop from working with chemical manufacturers; it began 25 years prior while in operation on an asphalt shingle production. A client came to us asking to remove PFAS and PFAS emissions from their process stream. From experience, our engineers knew that asphalt process exhaust contains a variety of particle sizes (ranging from submicron and larger,)so their objective would be to control the opacity and associated odor resulting from the particulate emissions as well as address the PFAS. A Coalescing FiberBed Filter Mist Collector System was chosen for the application because of its ability to remove aerosols. However, with all of the stone dust present an Indexing Pre-Filter was needed to protect the main filters from clogging and to extend their life. The FiberBed Filter systems can utilize either water or air to cool inlet temps. Using water if you have PFAS is not an issue as long as you have water treatment equipment on location. For the majority of clients who do not then, we use an Air-to-Air Heat Exchanger (HXT). It provides cooling without any byproduct.

When Volatile Organic Compounds (VOCs) were present in the next project where PFAS were to be removed, then Air Clear’s Regenerative Thermal Oxidizer (RTO)was employed. The structured media inside of the RTO needs to be carefully selected so that it can withstand bakeouts and avoid SIO2 plugging. With a couple of proprietary technologies/designs, compounds, such as PFAS, which were previously too elusive to abate were now suddenly getting removed from the process streams.

When potential customers come to Air Clear looking for a system that will remove PFAS/PFOS from their air emissions then our team of engineers sits down with them and carefully reviews their application. Once we have a clear understanding of your process then we model the present and potential future regulations for the plant’s location. Are you looking for a short or long-term solution? Does your project have time constraints? Have you tried another abetment technology previously and what was the outcome? The list of questions goes on, but by taking the time to understand our clients and their projects we have been found it is the best way to successfully control PFAS emissions effectively and economically. Unbeknownst to us that by addressing the challenges proactively then our team was able to develop new approaches for the removal of the durable and heat resistant PFAS.

For first-hand stack test results from Air Clear’s equipment on our client’s looking to remove PFAS from their process stream in Upstate NY just click the following link – https://www.4cleanair.org/wp-content/uploads/Documents/Fall_2018_Gentile.pdf

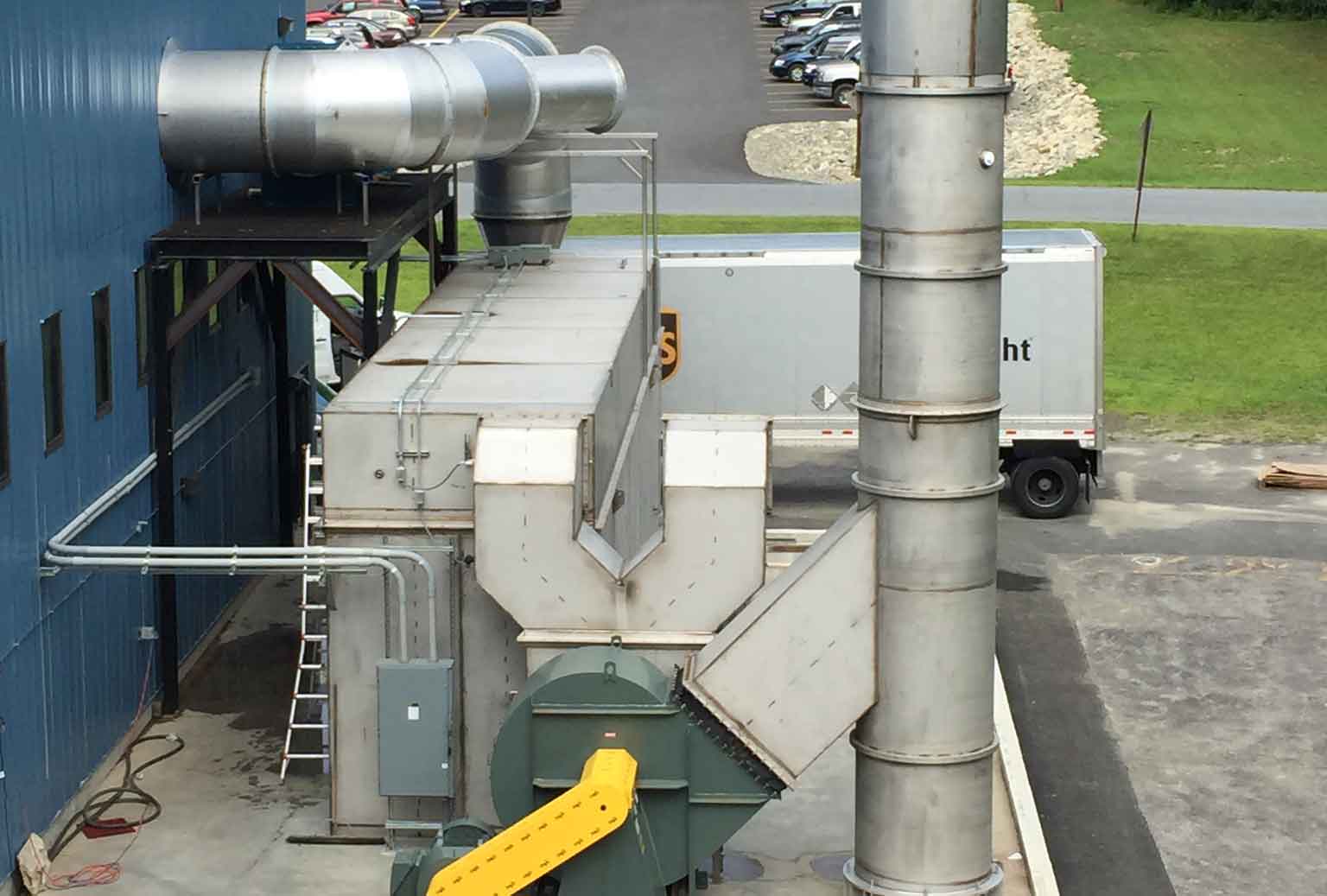

Air Clear’s Stainless Steel FiberBed Filter Unit removes PFAS in Upstate NY

Indexing Prefilter on the Unit helps to remove large particulate from air stream and prevent the FiberBed Filters from plugging up with stone dust

Aerial View of FiberBed Filter Unit, one of four on site. First installed 25 years ago

A valuable realization came to pass. If we employed different combinations of equipment styles in various industrial applications thenwe would be able to address previous Air Emissions that in the past were proving too difficult to mitigate. Air Clear’s three canister Regenerative Thermal Oxidizers are used to remove PFAS contaminants in various industrial applications.

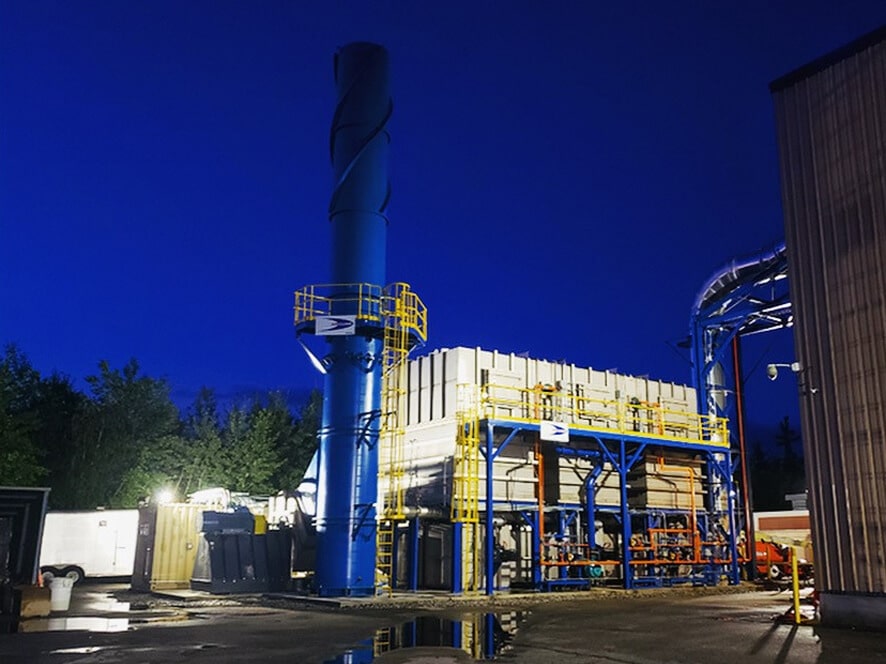

Stack test results from Air Clear’s equipment designed to remove VOCs & PFAS from the process stream of a client in Merrimack, NH – https://www4.des.state.nh.us/OneStopPub/Air/330110016521-0047TypeSTReport.pdf

Constructed in 2021, two separate locations where PFAS are eliminated with the use of an Air Clear Regenerative Thermal Oxidizer.

Resistant to most chemical and microbial conventional treatment technologies, Air Clear’s proprietary solution is a combination of extraction and filtration methods for PFAS removal in air emissions. To date Air Clear has successfully removed PFOS & PFAS with the use of our two and three canister Regenerative Thermal Oxidizer (RTOs), Thermal Recuperative Oxidizers (TRO) and FiberBed Filter Units (FBFs) with IPF (Indexing Pre-Filters) and CAC (Carbon Absorption Canisters).

In conclusion PFAS’s emissions and formidable carbon-fluorine bonds make them can be extremely difficult to breakdown. That coupled with the fact that most PFAS are both thermally and chemically stable,means that they demonstrate an incredible resistance to heat, making oxidation a much more complicated procedure. Luckily for our clients that manufacture or use PFAS in their application, we have developed a proven solution for the Air Pollution Control Technology needed to remove PFAS emissions from process air streams. Over the years Air Clear has had extensive experience in industries with both VOC and Aerosol particulate. This experience has led to an integration of Air Clear’s two primary products.

- 1. Coalescing FiberBed Filter Units – Removes submicron aerosol particulate

- 2. Oxidizers – Use a 3 “T” System to address PFAS & PFOS in process streams

Newly approved test methods and monitoring methods are being implemented to determine or model PFAS emissions levels from various industrial applications domestically. The EPA and various state agencies worked diligently on standardizing methods for testing levels of PFAS in source emissions/ambient air. That means that any facility that releases PFAS emissions into the air will be subject to permitting and other strict requirements under the new upcoming regulations from the EPA. All synthetic PFAS compounds will likely end up classified as Hazardous Air Pollutants (HAPs) by Congress. Whenthat happens PFAS emissions will become subject to strict limits and permitting requirements which will force companies to install control technology. Under CERCLA, any PFAS listed as HAPs will automatically be deemed hazardous substances. It also makes any source of pollution that “presents an imminent and substantial endangerment to public health or welfare, or to the environment.”to be shut down until action is taken. The writing is on the wall…if you have these hazardous substances in your factory stack air emissions, now is the time to take action with proven Air Pollution Control Technology to eliminate PFAS emissions.

At Air Clear we engineer/design, manufacture, install and service the highest quality Air Abetment Technology available on the market today. We understand how important it is for companies to purchase the correct air pollution control equipment the first time. If you have PFAS or PFOS in your process stream, contact our talented team today so that we can walk you through how we can help.

For more information on Clear Trends or to learn more about Air Clear’s products & services and proven design solutions to eliminate PFAS, then please visit our newly designed website at www.airclear.net

Steven Michael O’Connor

Jan 27th 2021

Clear Trends PFAS PART 2 rv11