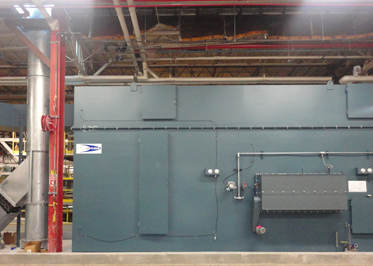

2500 SCFM Regenerative Thermal Oxidizer (RTO) preceded by Fiberbed Filter Mist Collector System on Asphalt Roofing & Shingle Manufacturing Process in New Jersey.

Carpet

manufacturing

The expansive industry of carpet manufacturing produces a variety of emissions. Through the manufacturing production process, various exhaust streams are emitted which contain toxic particles ranging in size from submicron to large. In order to mitigate the effects of these harmful particles, the resulting opacity, associated odor, and in some cases Volatile Organic Compounds from emissions must be controlled.

To achieve this objective, Air Clear offers the Coalescing FiberBed Filter Mist Collector to collect & control the submicron particulate driving the opacity. Air Clears FiberBed Filters are engineered to control solid & liquid particulate, comprehensively mitigating emissions & ensuring cost effectiveness in carpet manufacturing processes for decades.

15,000 ACFM Coalescing Fiberbed Filter Mist Collector System w/ indexing pre-filter on Textile Manufacturing Process. The Filter System was installed in an alley behind the Textile Plant.

25,000 ACFM Coalescing Fiberbed Filter Mist Collector System w/ indexing pre-filter on Carpet Manufacturing Process. The Filter System was installed inside of the building.

25,000 ACFM Coalescing Fiberbed Mist Collector with Indexing Pre-Filter on Carpet Manufacturing Process.

The images above depict three Air Clear Filter Units specifically designed and installed with indexing pre-filters to control emissions from a client’s carpet manufacturing plant. Air Clear manufactured and installed Filter Units that efficiently function inside and outside of the building. With durable poly pre-filter material, Air Clear’s Indexing Pre-Filter removes lint, waxes, and oil that accumulates from process exhaust prior to entering the main filter section. The Pre-Filter is designed to extend the life of the main filters. Without Air Clear’s sustainable pre filter technology, the filter media compiles dirt, the pressure drop increases, and a costly replacement is required.

Carpet Manufacturing processes may also produce harmful VOCs emissions that require proactive control. In these cases, Air Clear can offer turn key services to ensure that complete emission control is obtained and system longevity is protected. Air Clear designs and installs Regenerative Thermal Oxidizers (RTO) with Indexing Pre Filters to combat the emission of VOCs and the corrosion of equipment. The Pre-Filter implements durable poly pre-filter material to remove lint, waxes, and oil particulate before it enters the RTO. In effect, Air Clear’s pre filter technology will protect ceramic media from plugging and save carpet manufacturers substantial capital expenses in the form of replacement and maintenance.

30,000 CSFM regenerative (RTO) thermal oxidizer w/ prefilter. RTO is a roof mounted system.

12,000 ACFM coalescing fiberbed filter mist collector system on interface carpet manufacturing product line in Shanghai, China.