Catalytic Oxidizers (CATOX™) use a catalyst to promote the oxidation reaction to occur. Catalytic oxidation requires less than half the heat (500-600°F) needed for thermal oxidation (1,400-1,600°F) and creates an opportunity to substantially reduce fuel expenses and material costs. The addition of a Recuperative (heat exchanger) further reduces the need for supplemental fuel. In many cases, the system requires no supplemental fuel in an operating condition known as “autocatalytic”.

The Air Clear Advantage in Catalytic Oxidation

- Proven Conversion of hydrocarbons or VOCs to have negligible photochemical reactivity. Can be as high as 99.9% efficiency with 50% less energy use

- Lower operating temperatures result in lower NOX emissions, without significant formation of CO.

- Air Clear’s CATOX™ CATALYTIC OXIDIZER Systems are smaller and lighter than their thermal counterparts, requiring a smaller footprint.

- Our flameless catalytic electric heat systems do not generate NOX emissions.

- A variety of catalyst types are available to optimize performance for each particular application. Even halogenated organic compounds can be controlled with the proper catalyst.

- Requirements for MACT, BACT, LAER, and RACT making it the preferred oxidation technology for many applications.

- Air Clear Regenerative Catalytic Oxidizers Meet Federal, State and Local EPA Emissions Requirements Catalytic Oxidizers are recognized as the Best Available Control Technology (BACT) and Maximum Control Technology (MACT) for many industrial applications.

- Combination catalytic/thermal oxidizer systems are available for specialized requirements such as remediation projects such as soil vapor extraction.

- The Air Clear Catalytic Recuperative Oxidizer is designed to provide reliable stable operation over a wide range of process conditions – flows and VOC loadings – wide variety of processes. The Air-Clear CATOX™ is also an excellent choice for intermittent ‘ON-OFF’ use.

- Air Clear’s Custom Catalytic Oxidizer product design meets your specific environmental and project objectives in the most cost-effective way.

- Best Value Featuring primary and secondary heat recovery the Air-Clear Regenerative Catalytic Oxidizer can often MAKE YOU MONEY!

- Factory Acceptance Test (FAT) – reduces commissioning and start-up time by running a thorough diagnostic system check PRIOR to shipment. In house fabrication provides AC with the ability to maintain quality and delivery control at the lowest cost by eliminating Second tier fabricators.

When a Catalytic Thermal Oxidizer is required to prevent the emissions of hydrocarbon solvent vapors (VOCs) into the atmosphere, Air Clear also looks for ways to recover as much energy as possible and redirect it to the manufacturing process.

Air Clear Specialty

Catalytic Products

Cat-Denox™ Selective Catalytic Reduction (SCR) NOx Control System

Air Clear, Inc. takes pride in assisting companies in diverse industries meet their stringent emission limits with intelligent solutions that easily integrate into existing operations. Air Clear designs, engineers, fabricates, and services the most advanced air pollution and hazardous waste control equipment available.

Meeting the new, stringent regulations for NOx emissions is of foremost concern for the operators and developers of both power plants and industrial processes. The CAT-DENOX SCR offers the best choice for combining low emission values; high removal efficiency; and long-term, cost effective compliance. Please contact Air Clear for more information on how SCR can be successfully and cost-effectively integrated into a comprehensive NOx compliance plan.

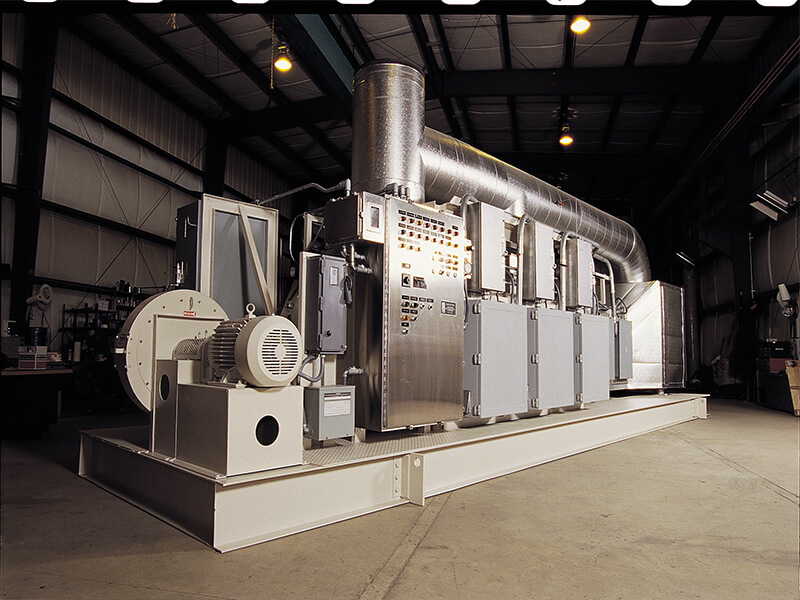

AIR CLEAR CATOX FOR GRANULES PHARMACEUTICAL IN CHANTILLY, VA

The Air Clear Advantage

in SCR Systems:

Flexible Design

- Ammonia source of Anhydrous, Aqueous or Urea

- Ammonia vaporized using electric heater or heat from exhaust gas

- Retrofit into limited space

- Vertical or horizontal gas flow

- Custom designed to optimize performance and cost effectiveness

- Wide Temperature Range. (350°F to 1,150°F)

Single Source Responsibility

– Full Scope of Supply

- Responsibility for Performance Guarantees and Equipment Warranties

- Computer and Physical Modeling of Process

- Permitting and CEM Certification Support

- Turnkey Installation Available

Ultra-Low Emissions

- NOx emissions down to 2 ppm

- Ammonia slip down to 2 ppm

- CO reduction up to 99% can be included

Wide Range of Applications

- Simple Cycle Turbine

- Heat Recover Boilers (HRSG)

- Package Boiler

- Diesel Engine

- Glass Furnace

- Steel Reheat Furnace

- Process Heaters

- Waste Incinerators

- Many Others

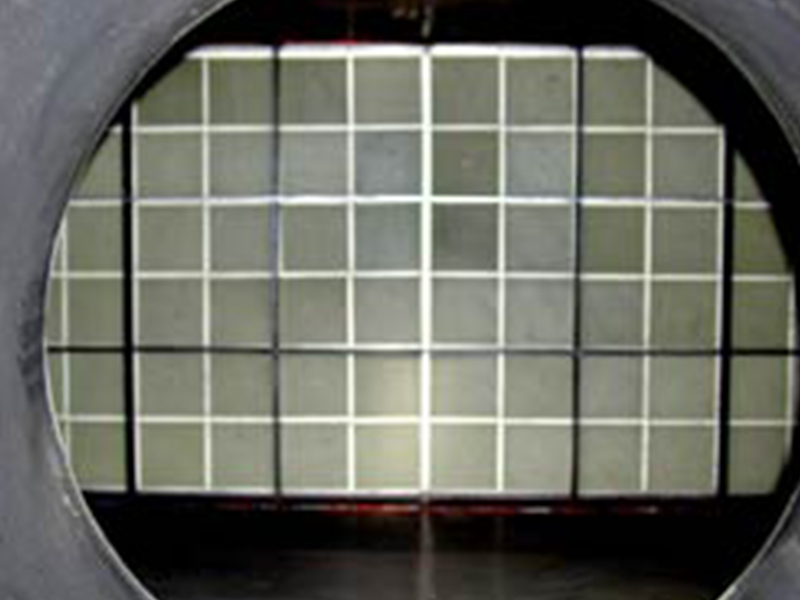

CATALYST BLOCK

CATALYST BLOCK INSTALLED IN A CATALYTIC OXIDIZER

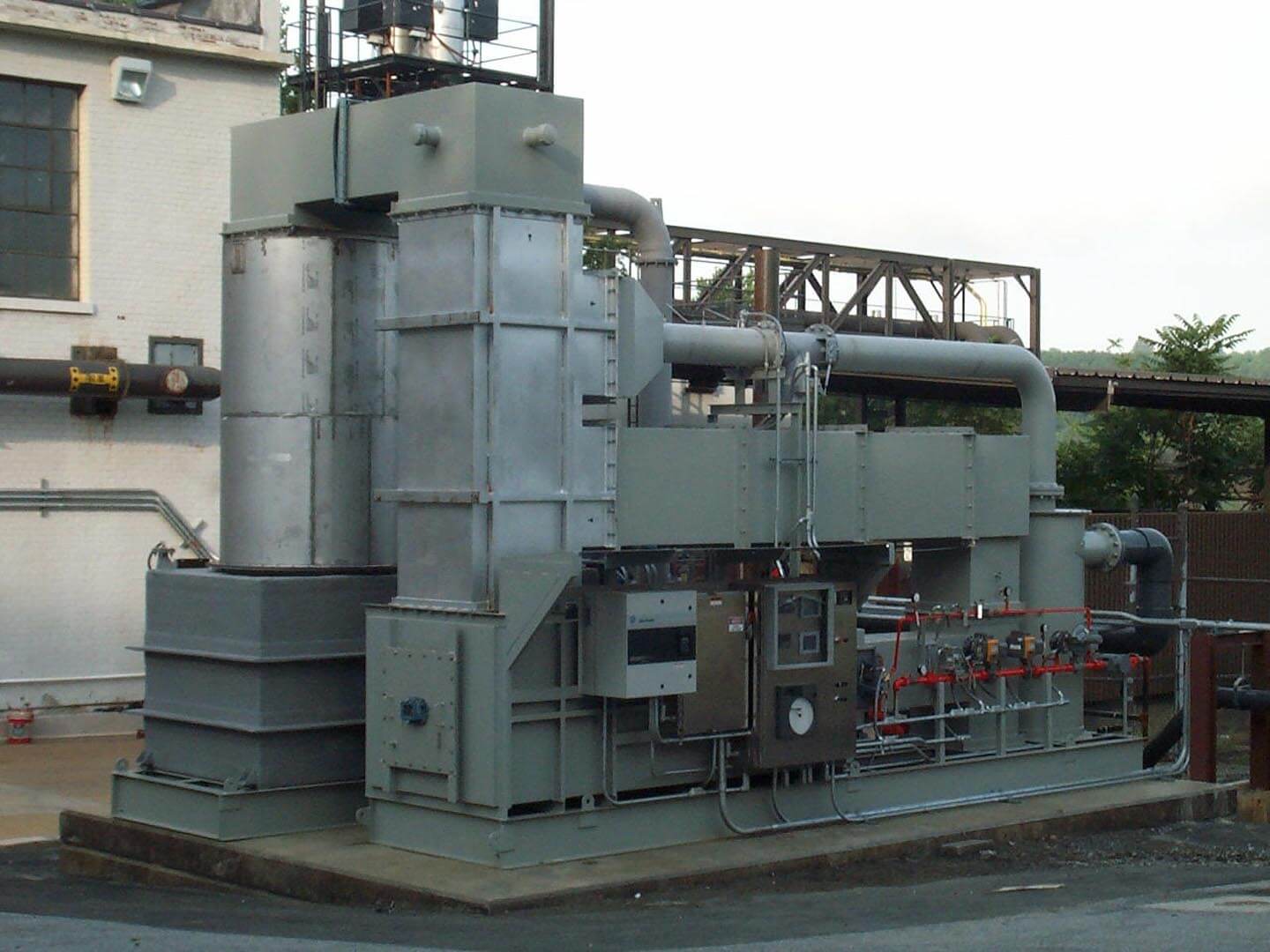

20,000 SCFM CATALYTIC OXIDIZER WITH 68% PRIMARY HEAT RECOVERY

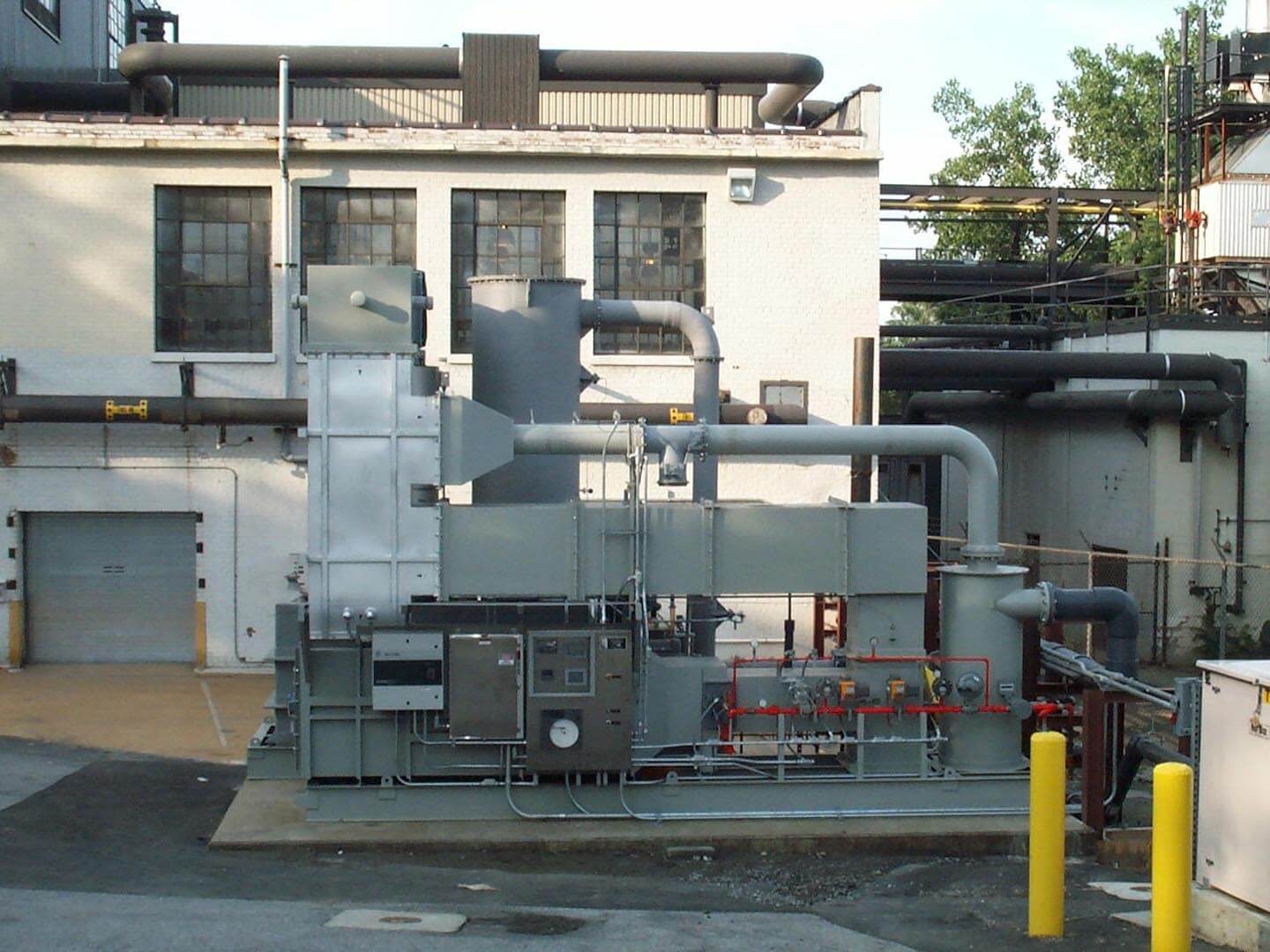

INSTALLATION OF SKID MOUNTED CATALYTIC OXIDIZER ON UPJOHN PHARMACEUTICAL PROCESS

10,000 SCFM SKID-MOUNTED CATALYTIC OXIDIZER WITH 68% HEAT RECOVERY EFFICIENCY

AIR CLEAR WELDERS INSTALL STEEL PLATE IN COMBUSTION CHAMBER OF CATALYTIC OXIDIZER